Food packaging concepts for the circular economy

Content

- Food packaging concepts for the circular economy

- 1 Introduction

- 2 Basic principles of the circular economy

- 2.1 Definition of terms

- 2.2 Goals and principles

- 2.3 Ecodesign and design for recycling

- 3 Regulatory framework conditions

- 3.1 UN Sustainable Development Goals (SDGs)

- 3.2 EU Plastics Strategy

- 3.3 EU Circular Economy Action Plan (CEAP)

- 3.4 EU Waste Framework Directive and German Circular Economy Act (Kreislaufwirtschaftsgesetz – KrWG )

- 3.5 EU Packaging Directive and German Packaging Act (Verpackungsgesetz – VerpackG)

- 3.6 Proposal for a Regulation on Packaging and Packaging Waste

- 4 Incentives and potential

- 4.1 Economic incentives – system participation fees and production costs

- 4.2 Ecological incentives – resource conservation and reduction of potential environmental impacts

- 4.3 Social incentives – fulfilment of consumer expectations

- 5 Challenges and limitations

- 6 Summary, conclusion and outlook

- Literature

- contact

1 Introduction

Raw materials1, which are extracted from the environment and utilised, form the material basis of the economy. In recent decades, the extraction of raw materials has increased drastically worldwide and the economy has experienced continuous growth. Compared to 1970, almost three times as many raw materials are consumed today, with a doubling in the last 20 years. [2, 3] The drivers for the increasing consumption of raw materials are probably not only the world population, which has more than doubled since 1970 [4] but also consumption trends in developed countries and the economic growth taking place in emerging and developing countries [5, 6] and the associated increase in consumption [3]. However, there cannot be infinite growth in a world with finite resources [7-9]. This applies both to individual consumption and to reconceptualising the production of the underlying patterns of value creation [10]. Resource efficiency [6], circular economy and sustainable supply chains are just as necessary as the avoidance and responsible handling of “waste” [10]. In addition to the ecological and social reasons, there are also economic reasons in favour of a fundamental change from today’s predominantly linear economy to a resource-efficient circular economy [5]. In many cases, the European economy is dependent on imports of raw materials. This dependence could increasingly become a source of vulnerability as growing global competition for natural resources has contributed to a significant increase in price levels and price volatility. Even if resources are not scarce in absolute terms, many natural resources are unevenly distributed around the world, making access and prices more volatile and exacerbating the potential for conflict. [6]

The need to move towards a resource-efficient circular economy also affects the packaging industry. This applies in particular to packaging for fast-moving consumer goods (FMCG), which includes most food products. FMCG packaging has a short use phase of a few days or weeks [11] and symbolises today’s throwaway society [12, 13] which is also known as the linear economy and is often described as “take-make-waste” [13-16].

European policymakers are responding to environmental challenges with a variety of roadmaps and resulting legislation, including the European Green Deal. One aim of the Green Deal is to develop measures to combat unnecessary packaging in order to reduce waste [17]. To promote the circular economy, the Circular Economy Action Plan (CEAP) is a central element of the Green Deal. The CEAP aims to decouple economic growth from resource use and at the same time ensure the EU’s long-term competitiveness. [13] In line with the aim of the Green Deal to combat unnecessary packaging [17] a proposal for a new European regulation on packaging and packaging waste (PPWR) has emerged from the CEAP [18].

In addition to politics, the packaging and food industry finds itself caught between the poles of environmental protection, economic growth and social justice [19], where more sustainable packaging design represents a challenge. The key role for the environmental compatibility of food packaging lies in the specific adaptation of the packaging properties to the food requirements. In most cases, most of the total resource consumption of the product packaging system is associated with the food and not the packaging. Functional packaging with adequate product protection can prevent food wastage [20, 21] e.g. by extending the best-before date or use-by date [22]. The protective function of packaging should therefore be given top priority when it comes to reducing the waste of resources and unfavourable potential environmental impacts. Plastics in particular can fulfil the sometimes high requirements for product protection on the packaged goods side with relatively low material usage compared to other packaging materials and are therefore highly efficient [23-25]. This is probably one of the reasons why plastic-based food packaging in Germany accounted for the largest market share of packaging materials in terms of sales in 2020 at 41% [26]. The environmental benefit of avoiding food wastage, especially for resource-intensive foods such as meat, is around 5-10 times higher than the environmental impact of the packaging [22]. Functional packaging therefore has the potential to reduce potential environmental impacts by avoiding packaging-related food wastage [27].

Despite the potential of functional packaging to reduce potential environmental impacts [27] they are controversially discussed in sustainability debates, partly due to the increasing volume of packaging and packaging waste, and their contribution to reducing environmental impact is not highly valued [28, 29]. Germany contributed to this increasing packaging volume in 2018 with a new high of approx. 18.86 million tonnes of packaging consumption nationwide [30]. This can lead to various environmental issues if packaging waste is released into the environment, for example due to improper disposal. This results in terrestrial and aquatic environmental pollution, which has already been publicly addressed [19]. Explicitly, the environmental discharge of plastics is an issue of increasing importance [31-33]. In addition to directly visible landscape pollution caused by packaging waste, plastic pollution can also have serious consequences for living organisms and human health. This includes nano- and microplastics as well as per- and polyfluorinated alkyl substances (PFAS) [34] found in soil, marine and freshwater ecosystems. It is important to address this issue to protect the environment and human health [32, 35-37]. The aforementioned environmental consequences in combination with the high proportion of plastics used for food packaging are reasons why no other packaging material has been subject to comparable legal measures, such as the so-called “Single-Use Plastics Directive” [38]. However, this does not mean that other packaging materials are generally associated with lower potential environmental impacts than plastics [39].

Fact is that recyclable materials, such as plastic packaging waste, which are circulated as secondary raw materials, are less likely to end up in the environment than non-recyclable products. A circular economy for plastics can therefore contribute to reducing the amount of plastic entering the environment and its consequences. [40]

Against the background of the global challenges that require a circular economy, the resulting legal frameworks and the tension between functionality and recyclability of food packaging, the following key question of this expert report arises.

“To what extent is the concept of a circular economy essential for food packaging and what strategies enable successful implementation?”

1 Raw materials are extracted reserves that are required for the production process of goods. In contrast, resources are proven but currently technically

and/or economically unrecoverable and unproven but geologically possible future recoverable quantities of raw materials. [1].

2 Basic principles of the circular economy

2.1 Definition of terms

In Germany, the concept of the circular economy is closely linked to the awareness of a functioning waste management system. Separate waste collection in combination with constantly evolving sorting and treatment facilities enable a recycling economy in which waste is seen as a raw material and material cycles are closed. [41] The circular economy within the meaning of the german Circular Economy Act (Kreislaufwirtschaftsgesetz – KrWG) explicitly includes the prevention, reuse, material recycling and thermal recovery as well as the disposal of waste [42].

The Circular Economy (CE) according to the EU’s CEAP goes beyond the mere treatment of waste. The CE encompasses a systemic change in the economic system. It also addresses fields of action such as employment and growth, climate and energy, the social policy agenda, industrial innovation, product design, processing and, last but not least, resource efficiency and resource conservation. [13]

In addition, there are numerous definitions of a circular economy from various initiatives, such as the Ellen MacArthur Foundation or for different concepts such as zero waste or Cradle-to-Cradle (C2C) [43]. The concepts and fundamental goals of a circular economy often overlap. They can be described as follows:

2 PFAS (per- and polyfluorinated alkyl substances) are very stable and water, dirt and grease repellent. Due to these properties, they are used for a wide variety of applications such as outdoor equipment, cookware, dirt-repellent carpets or food packaging. [34].

2.2 Goals and principles

The aim of a circular economy is to preserve the value of products and the resources used for them for as long as possible and to generate as little waste as possible – ideally even none at all [5, 41, 43, 44]. This includes the reuse of used products and materials as well as the prolonged use, rather than consumption, of products in the sense of extending their lifetime and the intensified utilisation of consumer and industrial goods [5]. In this way, a circular economy should contribute to the conservation of natural resources, including climate protection, the protection of the environment [45] and human health [41]. Natural resources and human health can be protected in the generation and management of waste by using environmentally and climate-friendly disposal methods and reducing or avoiding pollutants in material cycles [6, 46] or specifically removing them from material cycles [41]. The unfavourable potential environmental impacts along the life cycle of products and materials should be reduced by saving primary materials and substituting them with secondary materials [41]. The entire life cycle, from raw material extraction through production, storage and consumption to disposal or recycling at the end of life, must be considered at both the material and energy levels [43].

The Cradle-to-Cradle concept is based on natural material cycles. There is no waste, only valuable resources. Each output of a process represents the input for another process. The concept divides materials and resources into two cycles – the biological cycle and the technical cycle. In both cycles, all materials should have no harmful environmental impact and be able to circulate permanently. Products that are designed for the biological cycle are referred to as consumable products. These include, for example, products that can actually be used up during their lifetime (e.g. through physical degradation or wear and tear). In the technical cycle, by contrast, materials or resources are circulated that have the potential to be managed in a closed cycle over many product life cycles without any loss of quality. [47] In practice, however, closed cycles, so-called closed-loop systems, are always associated with losses on the raw material side [41, 48].

The “3 R’s” – reduce, reuse, recycle – are principles that contribute to a circular economy [43, 49]. The principle of reduce aims to minimise the total amount of materials, resources [50], and waste generated in the economic model in order to reduce the harmful effects of the generated waste on the environment and human health [51]. The prevention approach can also include various zero-waste initiatives [41]. Reuse comprises processes in which products or individual product components do not become waste but are reused for the same purpose [51]. Recycling refers to any process in which waste materials are reprocessed into products or materials, whether for the original or another purpose [51]. In the context of the 3 R’s, waste prevention plays an overriding role, not least due to the waste hierarchy according to Directive 2008/98/EC (see chapter 3.4) [43].The prevention of waste and residual materials is generally preferable to recycling, as the latter always involves losses and energy expenditure [41]. Waste avoidance can be of a quantitative (reducing the amount of waste) and qualitative (reducing the content of harmful substances in materials) nature [41, 51]. Qualitative waste prevention, such as the production of low-pollutant and pollutant-free products, serves to reduce the release of pollutants during the use phase and the accumulation of pollutants during recycling [41]. Reducing the volume of waste [6] can be achieved, for example, through a longer lifetime or the reuse of products [41]. This is where the principles of reduce and reuse intersect.

In order to make a real contribution to reducing the demand for primary resources, it is necessary to realise high-quality recycling cycles [6] in which the material qualities of the recyclates are comparable to those of the corresponding primary raw materials. This requirement also underlies the Cradle-to-Cradle concept [47]. Downcycling, that produces lower-quality recyclates in which functional materials are irretrievably lost or contaminants accumulate, should be avoided wherever possible [6]. The lower-quality recyclates produced in this way often end up in (technically) less demanding applications in which they do not have the same environmental relief potential. Otherwise, the lower-quality recyclates must be mixed with primary raw materials to such an extent that they once again fulfil technical or regulatory quality requirements. [41] Where high-quality recycling is not possible, cascade utilisation of products and materials should be aimed for [6].

If waste avoidance, reuse and high-quality recycling as well as the cradle-to-cradle concept are taken into account in the product design process, products can be designed from the outset that do not become waste [6] or are recycled at the end of a product life cycle [43].

3 Cascade utilisation refers to the use of resources and products in successive steps, each with reduced requirements in terms of properties. The aim is to keep resources and products in the system for as long as possible so that a high level of added value is maintained. [52].

2.3 Ecodesign and design for recycling

Up to 80% of the potential environmental impact of a product is already predetermined in its design process [53, 54]. Design approaches such as design for recycling (D4R) or ecodesign are therefore indispensable elements when it comes to reducing the potential environmental impact of products. Ecodesign is an approach that aims to incorporate environmental concerns into the life cycle of products at an early stage of product planning, development and design. The aim is to develop products that require as few resources and as little energy as possible for optimum functionality and contain only a minimum of pollutants – or none at all [6]. Ecodesign also aims to minimise emissions and waste. [53] The objectives of ecodesign largely overlap with those of a circular economy. Some of the product aspects that are included in the proposal for a new ecodesign regulation [55] which are also addressed in the context of the circular economy are, for example

- the use of recyclates

- reusability

- the ability to retrofit and repair

- the presence of substances of concern

- waste materials likely to be generated

- the possibility of reprocessing and recycling as well as the recovery of materials

Various guidelines offer assistance with the ecodesign of products [56-58]. The guidelines of the Round Table on Plastic Packaging exist specifically for the ecodesign of plastic packaging [59].

Recyclability is a relevant product aspect in the overarching context of ecodesign [60]. In order to design products to be recyclable, various requirements must be taken into account. Specifically for packaging, the minimum standard for assessing the recyclability of packaging subject to system participation of the Central Agency Packaging Register (Zentrale Stelle Verpackungsregister – ZSVR) [61] provides guidance on the conditions under which packaging is considered recyclable in Germany. The existence of a sorting and recovery infrastructure, the sortability and separability of the packaging and any existing recycling incompatibilities are taken into account. [61]

Further guidelines and evaluation catalogues from various institutions such as Interseroh [60], Recoup [29, 62] or RecyClass [63] partly take into account the minimum standard of the ZSVR or supplement it. These guidelines and evaluation catalogues provide assistance on how packaging can be designed to be recyclable for European countries. Design for recycling encompasses all packaging components: from the packaging material to the label adhesive and printing ink [64]. When considering the environmental impact of a product packaging system, it is important to prioritize product safety, functionality, and consumer acceptance. Improving the recyclability of the packaging should aim to reduce the overall environmental impact of the product packaging system. However, it is important to note that recycling may not always be the most environmentally or economically viable option. [29]

context of the circular economy and food packaging. An overarching, common goal of the

regulatory frameworkspresented is to reduce the impact of packaging and packaging waste

on the environment.

3 Regulatory framework conditions

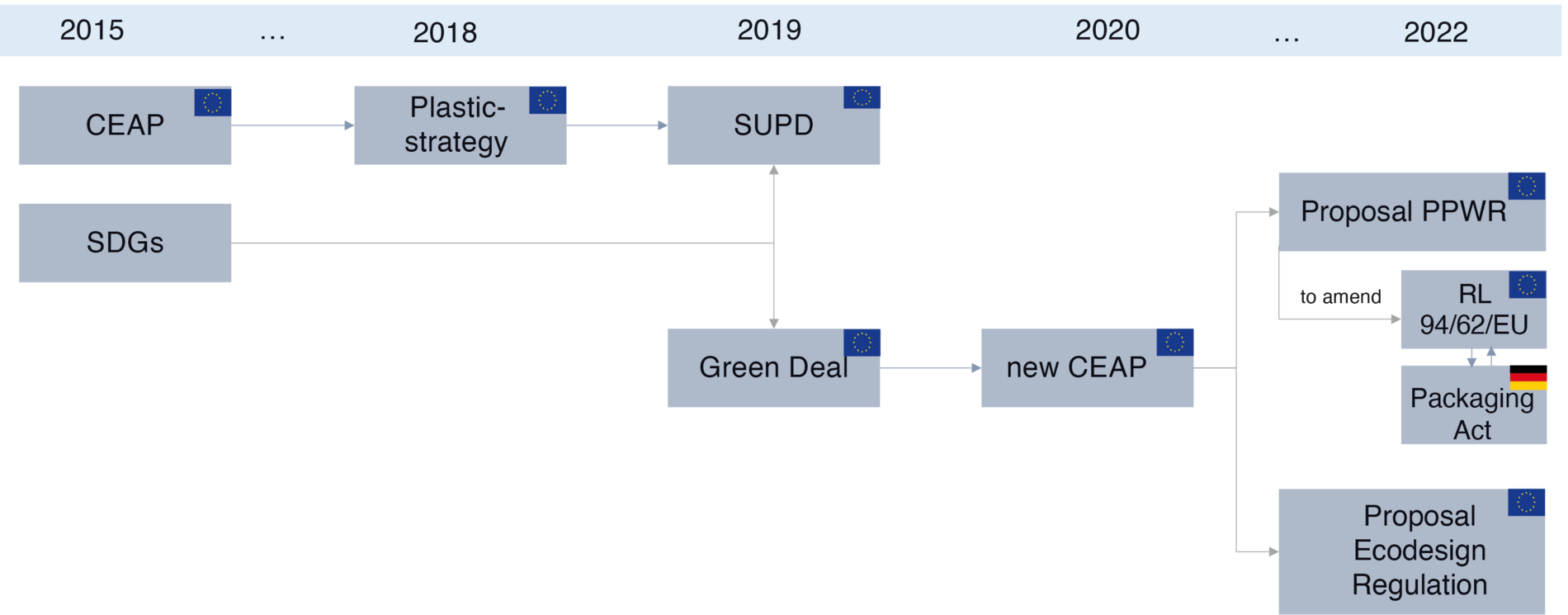

In the context of food packaging and the circular economy, the regulatory frameworks shown in Figure 1 are relevant. These are discussed in the following chapters 3.1 to 3.6 in more detail.

3.1 UN Sustainable Development Goals (SDGs)

The 17 SDGs (see Figure 2) are political objectives of the United Nations that are intended to ensure sustainable development on an economic, social and ecological level worldwide. Food packaging with effective product protection and efficient use of materials has the potential to contribute to achieving the SDGs.

SDG 12.34 in particular is addressed by food packaging [66]. Indirectly, food packaging can also help to achieve SDG 25, as there is a lack of capacity for packaging in poorer countries in particular [68] but can support logistics and distribution and thus contribute to food security. Packaging that, in addition to providing adequate product protection, is also designed to be material- and therefore resource-efficient, also addresses SDGs 12.26 and 12.57 [69]. If packaging functionality, high material efficiency and recyclability are to be realised to the same extent, this can result in conflicting objectives. An increased protective function through e.g. multilayer composites is usually associated with reduced recyclability, whereby the ecological benefit of improved protective function is often higher than the ecological disadvantage of reduced recyclability [70].

The contribution to the SDGs made by implementing a circular economy in the company can be included in the company’s sustainability strategy or potentially also be published in a sustainability report.

3.2 EU Plastics Strategy

The 2018 EU Plastics Strategy is part of the (old) EU Circular Economy Action Plan and a key element in Europe’s transition to a low-carbon circular economy. The Plastics Strategy aims to contribute to achieving the Sustainable Development Goals by 2030. The Plastics Strategy also aims to transform the way plastic products are designed, manufactured, used and recycled in the EU. This should also reduce the EU’s dependence on imported fossil fuels. The aim is also to improve environmental protection and reduce greenhouse gases and marine litter. To achieve this, the EU Plastics Strategy includes the EU Directive on Single-Use Plastics (Directive (EU) 2019/904 – (SUPD)). [71] The SUPD aims to prevent and reduce the impact of certain plastic products on the environment, in particular the marine environment and human health. To this end, the SUPD prohibits, for example, the placing on the market of single-use plastic cutlery, plates and drinking straws. [72]

However, the ban on certain single-use plastic items led less to a reduction in single-use items in general and more to their replacement by single-use items made of fibre based materials such as paper and board [73]. The replacement of lightweight plastic packaging with heavier materials results in an increase in packaging waste due to the increased material usage [74]. It is important to consider that packaging materials other than plastic can also have potential environmental impacts that may even exceed those of plastics. Therefore, substituting plastics with other packaging materials only shifts environmental impacts rather than reducing them. [39] In the case of the use of materials with lower functionality, such as paper and board [75] more packaging-related food wastage can also be generated, which further increases the potential overall environmental impact of the product packaging system [76]. In addition, aluminium or plastic coatings are often required to functionalise fibre based packaging so that it can adequately protect foodstuffs [39]. These composites, in turn, can only be recycled to a limited extent or not at all [74].

3.3 EU Circular Economy Action Plan (CEAP)

The CEAP aims to expand the circular economy and should also contribute to decoupling economic growth from resource utilisation. At the same time, the long-term competitiveness of the EU is to be secured. To this end, the CEAP aims to reduce waste and ensure that the EU has a well-functioning internal market for high-quality secondary raw materials. Supplementary legislative proposals should, for example, increase the proportion of recycled materials in products and enable reprocessing and high-quality recycling. [13]

Central product value chains are prioritised. These are selected on the basis of their potential environmental impact and their circular potential. Packaging also represents such a central product value chain. In this regard, the CEAP envisages reviewing the existing Packaging Directive (Directive 94/62/EC) and considering measures on the following aspects: [13]

- Reduction of packaging and packaging waste

- Promoting design with a view to the reuse and recyclability of packaging

- Testing the reduction in the complexity of packaging materials, including the number of materials and polymers used

- Binding requirements for the proportion of recycled material, especially for plastic packaging

- Review the possibility of introducing EU-wide labelling to facilitate the correct separation of packaging waste at source.

These aspects are addressed in the proposal for a regulation on packaging and packaging waste (see chapter 3.6).

The CEAP also provides for the definition of rules for the safe recycling of plastics other than polyethylene terephthalate (PET) for use as food contact materials. [13] The use of recycled plastics in food packaging is regulated by Regulation (EU) 2022/1616 on recycled plastic materials and articles intended to come into contact with food [77]. Two recycling technologies for PET are currently authorised under Regulation (EU) 2022/1616, which result in recyclates that can be used for food contact.

4 Halving per capita food waste at retail and consumer level and reducing it along the production and supply chain by 2030 [65]

5 Creating a world without hunger by 2030 [67]

6 Achieve the sustainable management and efficient use of natural resources by 2030 [65]

7 Significantly reduce the volume of waste by 2030 through prevention, reduction, recycling and reuse [65]

3.4 EU Waste Framework Directive and German Circular Economy Act (Kreislaufwirtschaftsgesetz – KrWG )

The KrWG as amended in March 2023 serves to implement the European Waste Framework Directive (Directive 2008/98/EC). The aim of the KrWG is to promote the circular economy to conserve natural resources and to ensure the protection of people and the environment in the generation and management of waste. The KrWG sets out regulations on the prevention, recovery and disposal of waste as well as other waste management measures. According to the waste hierarchy, the prevention and waste management measures are in the following order: [42]

In the context of food packaging, it should be noted that the avoidance of packaging, in accordance with level 1 of the waste hierarchy, does not necessarily result in a reduction in the total volume of waste. Reducing the material used for food packaging or dispensing with it altogether can lead to an increase in food wastage. This happens when the protection of the products is no longer guaranteed or sufficiently fulfilled by the reduced or avoided packaging [20]. Material-efficient composite materials can be used for food packaging to fulfil product protection requirements [70]. However, these composite materials are generally associated with reduced recyclability (level 3 of the waste hierarchy) [41]. In contrast, a lot of packaging made from so-called monomaterials can be recycled. These in the industry so-called monomaterials can also include composite materials if the main component exceeds a mass proportion of 95% of the packaging composite and is sent for recycling [78]. The ZSVR understands recyclability of packaging to mean that this packaging is basically suitable for replacing virgin material in material-specific applications after passing through industrially available recovery processes [61]. A distinction is made between theoretical, practical and true recyclability and the following definitions are used as a basis. Theoretically recyclable packaging is packaging that can be recycled in terms of the material it is made of and in its original condition without contamination. This does not take into account whether a recycling infrastructure exists for this material and no tests are carried out on theoretical recyclability. Packaging is considered practically recyclable if it can be recognised in a sorting plant and sorted into a fraction. Furthermore, a recycling process must exist for the material from which the packaging is made, which enables material recycling. In addition to recognisability, sortability and the existence of a process for material recycling, further criteria must be met for packaging to be considered truly recyclable. Only when packaging is actually collected, separated, marketed and utilised as a secondary raw material in the region where the packaging is generated as waste is it considered to be truly recyclable. [79, 80] Even for packaging that can be categorised as truly recyclable, there are hurdles to its recycling, for example if consumers do not feed the packaging into the appropriate recycling stream. For packaging materials that are theoretically and in some cases practically recyclable and are in circulation in relatively small quantities, the establishment of a separate collection, sorting and recycling infrastructure is often not economically viable. Packaging that cannot be recycled in the sense of material recovery is often sent for energy recovery. The thermal recyovery through incineration, in the sense of energy recovery, can partially compensate for the use of (fossil) fuels. However, as the energy from incineration can only be used once and materials are therefore removed from the cycle, material reuse and recycling processes are preferable to incineration wherever technically and economically possible [6]. In the context of thermal recycling of plastic packaging, the possible future application of Carbon Capture and Utilisation (CCU) offers a promising outlook. CCU not only enables the reduction of CO2 emissions from incineration, but also opens up the possibility of utilising the captured carbon as a raw material for the production of plastics and other materials. This contributes to the circular economy by using materials that would otherwise only be utilised for energy and thus removed from the cycle as a source for new products. This integration of CCU into waste management could therefore increase the efficiency of resource utilisation and at the same time reduce dependence on fossil raw materials. [81]

3.5 EU Packaging Directive and German Packaging Act (Verpackungsgesetz – VerpackG)

The Packaging Act as amended in October 2023 serves to transpose the European Packaging Directive (Directive 94/62/EC) into national law. The Packaging Act specifies waste management targets applicable to Germany and sets out general requirements for packaging. The following requirements are relevant in the context of the circular economy. The Packaging Act regulates the system participation obligation, collection, take-back and recycling of packaging. With regard to the participation fees, the Packaging Act requires that these be adjusted ecologically. This obliges systems to create financial incentives to promote the use of recyclable materials, recyclates or renewable raw materials. To measure recyclability, the Packaging Act refers to the minimum standard of the Central Agency Packaging Register (ZSVR). For single-use drinks packaging, deposit and take-back obligations as well as the minimum recyclate content of certain single-use plastic drinks bottles are prescribed. The Packaging Act also aims to reduce the consumption of certain single-use packaging, e.g. through reusable alternatives for single-use plastic food packaging and single-use beverage cups. [78]

The Packaging Act and the EU Packaging Directive set targets for the recycling of packaging in Germany and the EU. These targets are listed as SHOULD with the respective time horizon in the Table 1 and are compared with the actual recycling rates (IS) in Germany and the EU.

Table 1: Targets for the recycling of packaging (SHOULD) according to the Packaging Act and Directive 94/62/EC and actual

recycling rates (IS) of packaging by type in Germany and the EU. [78, 82] The recycling rates according to the Packaging Act

(SHOULD) and ZSVR (IS) refer to material and energy recycling. Only for plastics is the proportion of mechanical recycling

listed separately, as specified in the Packaging Act. The recycling rates of Directive 94/62/EC (SHOULD) and eurostat (IS) refer

to material recycling.

The IS values of the recycling rates for Germany are composed as follows:

eurostat column: recycled share of packaging waste generation of the respective packaging material [83]

ZSVR column: packaging quantities that were recycled in relation to the packaging quantities of the respective packaging

material reported as part of the system participation obligation. As, for some packaging materials, less packaging is reported

under the system participation requirement than is actually placed on the market, recycling rates of over 100% occur here [84].

| Packaging material | Recycling rates in Germany | Recycling rates in the EU | |||

| IS in 2021* | SHOULD from 2022 according to VerpackG [78] | IS in 2021 [83] | SHOULD by 2025 according to DIRECTIVE 94/62/ EC [82] | ||

| eurostat [83] | ZSVR [84] | ||||

| Paper and Board | 85 % | 91 % | 90 % | 83 % | 75 % |

| Plastics (material recycling) | 48 % | 66 % | 63 % | n.a. | n.a. |

| Plastics (energy recovery + material recycling) | n.a. | 110 % | 90 % | 90 % | 50 % |

| Glass | 80 % | 85 % | 90 % | 76 % | 70% |

| Metal | 83 % | n.a. | 90 % | 75 %* | n.a. |

| Aluminium | n.a. | 113 % | 90 % | n.a. | 50 % |

| Ferrous metals | n.a. | 100 % | 90 % | n.a. | 70 % |

*IS value is not stated separately for aluminium and ferrous metals, but exceeds both targets

As shown in Table 1 the EU targets for 2025 will be met or exceeded on average by the EU Member States and especially by Germany for paper and board, glass and metal packaging in 2021. The target for material recycling of plastics has not yet been met. The achievement of the German targets in accordance with the Packaging Act is measured by the recycling rates determined by the ZSVR. Only the target rate for glass is not achieved. In the actual values for Germany, the first value mentioned in each case comes from eurostat [83], whereby the share of recycled packaging waste in the packaging waste volume of the respective packaging material is specified. The second value in each case comes from ZSVR [84] where the ratio of recycled input quantities to the packaging quantities of the respective packaging material reported as part of the system participation obligation is specified. The IS values of the ZSVR are significantly higher than the IS values of eurostat and in some cases even exceed 100%. The values above 100% are due to the fact that less packaging was reported under the system participation obligation in 2021 than was actually placed on the market in 2021 and generated as packaging waste. This suggests that the distributors of packaging are under-participating in the systems [84].

The current European Packaging Directive aims to harmonise the regulations of the Member States in the area of packaging and packaging waste management. This is intended to prevent or reduce the environmental impact of this waste in all Member States and third countries in order to ensure a high level of environmental protection [82]. However, the form of a directive allows for different national implementation concepts, which is why the Packaging Directive was unable to achieve the desired harmonisation. It was also found that the existing Packaging Directive did not sufficiently address challenges such as the growing volume of packaging waste, obstacles to the recycling and reuse of packaging and the low recyclate quality of plastic packaging. This has made it clear that greater harmonisation is needed and that the harmonised packaging-specific rules should take the form of a regulation rather than a revision of the current directive. Against this background, on 30 November 2022, the European Commission published a proposal for a Regulation on packaging and packaging waste – PPWR. [18]

3.6 Proposal for a Regulation on Packaging and Packaging Waste

The proposal for the PPWR pursues three main objectives:

Minimising packaging and promoting reusable and refillable packaging to reduce the amount of packaging waste.

Promote a high-quality closed recycling loop by ensuring that all packaging placed on the EU market can be recycled economically by 2030.

Reducing the demand for primary raw materials and creating a well-functioning market for secondary raw materials by increasing the proportion of recycled materials in packaging materials through binding targets. [18]

Achieving the targets for the proportion of recyclate in packaging for food is a challenge for the plastic packaging industry. Due to the low number of authorised recycling processes in accordance with Regulation (EU) 2022/1616, there is not a sufficient quantity of plastic recyclates of the appropriate quality for food contact materials available. Particularly in the case of polyolefins, which are significant in terms of volume, the amount of recyclate processed would have to be increased more than fivefold. With the exception of PET, there are currently no authorised plastic recyclates for use in packaging with direct food contact. Plastic recyclates other than PET may only be used in food packaging behind a functional barrier. In the shortest possible time, recycling technologies would have to be further developed and authorised, capacities built up and separate waste collection boosted throughout Europe in order to provide the required quantities and qualities of plastic recyclates for the packaging market. [74]

The European Parliament’s amendments to the PPWR proposal address the challenge of recycled content in plastic packaging, especially in food packaging. The European Parliament therefore exempts packaging from the mandatory recycled content if this recycled content conflicts with European food safety requirements. The European Parliament is also calling for a review of the extent to which the use of bio-based raw materials can be counted towards the mandatory recycled content. [85]

4 Incentives and potential

The recyclability of food packaging is expected to be increasingly required by law from 2030 at the latest, not least due to the expected entry into force of regulatory frameworks such as the proposals for the PPWR and the Ecodesign Regulation. Compliance with these legal requirements will be mandatory in order to be able to continue placing products and food packaging on the market. However, there are also economic, ecological and social incentives for the design for recycling of food packaging that go beyond the legal obligation.

4.1 Economic incentives – system participation fees and production costs

Section 21 of the Packaging Act stipulates the creation of incentives as part of the ecological adjustment of system participation fees (see chapter 3.5) [78]. However, the Packaging Act does not specify how these requirements are to be implemented quantitatively and thus leaves the ecological adjustment of the system participation fees to the systems8. Accordingly, the required incentives may vary from system to system and may also be so low that they may not be perceived as incentives by producers. It is therefore to be welcomed that the further development of a concrete legal implementation of the ecological adjustment of the participation fees is planned as part of the revisions to the Packaging Act [86].

According to eurostat, the EU imports around 40% of the raw materials it consumes [87]. A circular economy can reduce the demand for primary resources by preserving materials used in products that are repaired or reused and by recycling waste as high-quality secondary raw materials [13, 46]. This would help to reduce Europe’s dependence on imports.

The supply chains of many industrial sectors would also be less vulnerable to price fluctuations on the international raw materials markets and to supply insecurity due to raw material shortages and/or geopolitical factors [6].

In Germany, a circular economy would reduce costs in the areas of mobility, food and housing by 25% (300 billion euros) by 2030 compared to 2012 [88], in the EU by 25% (1,800 billion euros) as well [15]. By establishing a circular economy, European households can save up to 80%9 of their costs in the areas of mobility, food and housing by 2050 compared to the average household expenditure incurred in 2012 [88].

8A system collects the empty packaging that accumulates as waste from private final consumers in its catchment area and sends it for recycling [78], e.g. yellow bag or yellow bin.

9 It is not possible to provide a quantitative value based on the specified source.

4.2 Ecological incentives – resource conservation and reduction of potential environmental impacts

The reuse and recycling of products slows down the consumption of natural resources. This reduces the destruction of landscapes and habitats and curbs the loss of biodiversity. Another benefit of the circular economy is a reduction in total annual greenhouse gas emissions. [54] According to a study by the Ellen MacArthur Foundation, a European circular economy in the mobility, food and housing sectors could reduce CO2 emissions by 48% 10 by 2030 compared to 2012. A reduction of 83% 11 is forecast by 2050. [15] With regard to packaging, it should be noted that the use of recyclates is often associated with reduced energy requirements in the production of packaging materials and thus with lower potential environmental impacts than the use of primary raw materials [89, 90]. Every tonne of recycled plastic used instead of virgin material avoids between 1.4 and 3.2 tonnes of CO2 equivalent [91*]. A can made from 100% recycled aluminium, for example, requires 95% less energy to produce than a conventional can made from raw aluminium [91]. The use of recycled glass can reduce the melting energy required by 3% and the associated CO2 emissions by 3.6% for every 10% of cullet used [92]. When recycling tinplate, up to 75% of the energy required for primary production can be saved. At the same time, the associated CO2 emissions are reduced by up to 80% and water consumption by up to 40%. [93] When paper is recycled, around 50% of the energy required and around 67% of the water required can be saved compared to the production of primary fibre paper. Approximately 1.2 kilograms of waste paper are used to produce one kilogram of secondary fibre paper, which can save up to 2.2 kilograms of wood. [94]

10It is not possible to specify an absolute value on the basis of the specified source.

11 It is not possible to specify an absolute value on the basis of the specified source.

4.3 Social incentives – fulfilment of consumer expectations

The fulfilment of consumer expectations represents a further incentive for the design for recycling of food packaging. Consumers are demanding an increase in the recycling of packaging and the use of recyclable materials [95] as well as a greater switch to refill systems in retail. An expansion of the reuse [95] and deposit system is also welcomed by consumers. [96] The perceived recyclability of food packaging influences consumers’ purchasing decisions [97, 98]. Therefore, information on the recyclability of packaging [99] and its environmentally sound disposal [100] is also relevant for consumers. Packaging that consumers consider to be poorly recyclable is also perceived as less environmentally friendly than packaging that is easily recyclable [100].

Furthermore, the transition to a more circular economy can increase Europe’s competitiveness, stimulate innovation, boost economic growth and create jobs 12 [54]. The study “Economic Growth Potential of More Circular Economics” by the Waste Resources Action Programme shows that 1.2 to 3 million additional jobs are expected to be created in the European circular economy by 2030. In Germany alone, around 330,000 additional jobs are expected to be created. [5]

12 The European Parliament is basing this on a report by the Ellen MacArthur Foundation. This report shows what a circular economy could look like in Europe‘s most resource-intensive value chains – mobility, food and the building sector. There were not enough studies available to provide a quantitative forecast of the jobs associated with a circular economy. Overall, however, the studies analysed by the Ellen MacArthur Foundation also point to beneficial employment effects.

5 Challenges and limitations

In addition to the potential of a circular economy described above, it is also associated with challenges and limitations.

For a complete and thus absolute13 decoupling of economic growth from resource consumption, the principle of completely closed biological and technical cycles (see also cradle-to-cradle in chapter 2.2) offers potential. So far, however, such closed-loop systems cannot be realised without potential environmental impacts, as they always involve losses of raw materials and energy input [41, 48]. It is not only in reality that completely closed material cycles are a distant utopia. Even in theory, completely closed material cycles contradict the fundamental laws of nature, such as thermodynamics, as certain losses in quantity or quality are unavoidable. In addition, it is not possible to recycle materials without using energy or other inputs, such as water. [41, 43] If the energy used for recycling comes from fossil fuels, this represents a contradiction to the circular economy. This also shows that a circular economy focussed exclusively on material recycling is not sufficient to achieve long-term independence from finite resources [40]. Another related point is the basic availability of resources. For example, resources that are indispensable for individual processes or products and, above all, technologies in connection with renewable energies.

No suitable substitutes are yet known for these resources. The supply of these resources is jeopardised because demand exceeds supply, the static range14 is alarmingly small or the raw material deposits are concentrated in individual regions or countries. In view of the increasing demand for raw materials, even completely closed material cycles would not be sufficient to cover the predicted needs of industry [103]. This illustrates that the circular economy still poses conceptual challenges [43]. Furthermore, the transition to a circular economy is also associated with costs. These transition costs include, for example, investments in assets or in the development of new infrastructure, research and development, employee training, costs associated with the introduction of new requirements and temporary support for the industries affected. [15, 49, 104] Accelerating the introduction of the circular economy would increase these transition costs, which may explain why the circular economy has not yet been introduced more quickly and on a larger scale. [15]

In the context of food packaging, too few recyclates are authorised for food contact in order to establish a circular economy. In addition, the complete and separate collection and material recovery of post-consumer waste is particularly challenging. [41] Mixed post-consumer plastic waste from the yellow bin (applicable to Germany) must be sorted into different material streams. Due to additives and impurities, sorting is sometimes difficult and post-consumer plastic waste is often processed into low-grade recyclate. Advances in sorting technology based on digitalisation, robotics and artificial intelligence could improve mechanical recycling, but are not yet widespread due to higher costs. Alternatively, chemical recycling offers the opportunity to break plastic down into its basic building blocks, which can then be used as a starting material for new plastic or for the chemical industry. This technology has the potential to convert plastic waste that is difficult or impossible to recycle into high-quality products, but is still under development. [105] Against this background, the targets for the minimum proportion of post-consumer recyclate in food packaging envisaged in the proposal for the PPWR additionally represent a challenge for the food packaging industry [74]. The supply of recyclates, especially those of sufficient quality for use in food packaging, currently tends to fall short of demand. As a result, recyclates are often associated with even higher costs than primary raw materials. [89, 106] The reuse of products or packaging, e.g. in the form of reusable systems, cannot be assessed as advantageous across the board either. Although reusable systems can contribute to the avoidance or reduction of waste, whether they are ecologically and economically more expedient depends on many factors, such as transport and cleaning costs, and must be assessed on a case-by-case basis. [107]

13 In the case of absolute decoupling, resource consumption remains constant or even decreases. In the case of relative decoupling, resource consumption

increases less than economic growth, which is proportional to gross domestic product. [101].

14 The static range indicates the period of time for which the known raw material reserves would be sufficient for the given annual production volume of a raw

material. [102].

6 Summary, conclusion and outlook

The following can be summarised to answer the key question posed by this expert knowledge: to what extent is the concept of a circular economy indispensable for food packaging and which strategies enable successful implementation?

Against the backdrop of ecological necessity and the associated global challenges, such as the increasing volume of waste and the scarcity of finite resources, a change from a linear economy to a circular economy is imperative. This applies in particular to FMCG packaging, such as food packaging, which, due to its short use phase [11] symbolise today’s throwaway society [12, 13] and therefore a linear economy [13-16]. A circular economy offers the potential to reduce the use of primary resources, waste generation and the associated potential environmental impacts. However, in view of the scarcity of finite resources, the circular economy does not lead to independence from finite resources due to losses during the recycling process and the use of fossil-based energy sources. To address this limitation, a combination with a complementary alternative economy – the bioeconomy – is required. Equally important is the provision of improved product information for consumers. [6, 41, 49] It remains to be emphasised that even with the transition to a circular economy, there is a fundamental need to significantly reduce the overall consumption of natural resources for sustainable development [43].

Furthermore, especially in the context of food packaging, appropriate regulatory and technical framework conditions must be created in order to overcome the challenges already discussed with regard to the use of recyclates in food packaging. The entire product packaging system must always be considered when designing food packaging, taking into account the desired waste reduction, minimisation of potential environmental impacts and conservation of resources. The waste hierarchy and/or recyclability must not take precedence over the functionality of the packaging. Significantly more resources are tied up in food than in its packaging. If, for example, the functionality of the packaging is impaired by the design for recycling, this can result in higher potential environmental impacts than non-recyclable packaging if packaging-related food wastage increases. Even dispensing with functional packaging in the sense of the first stage of the waste hierarchy – prevention – can result in more potential environmental impacts when considering the product packaging system and taking into account the resulting food wastage than were saved by the avoided packaging. The first stage of the waste hierarchy can also be seen in the avoidance of food wastage, which often does not go hand in hand with the avoidance of packaging. Recyclability is not the same as the level of sustainability of the packaging. Considering this aspect alone distorts the results and, in case of doubt, can lead to more unfavourable potential environmental impacts and thus fail to achieve the goal of reducing environmental impact. Whether functional food packaging, even if it is not recyclable, is associated with lower potential environmental impacts requires an individual assessment. Sustainability assessment methods such as the Life Cycle Assessment, Life Cycle Costing or a Social Life Cycle Assessment can be used for this purpose.

The challenges facing a circular economy in the food packaging industry emphasise the need for research in this area. In the context of this research, a holistic view of product and material cycles across their life cycle and their dependencies on other cycles is a fundamental prerequisite for sustainable innovations. This includes the consideration of ecological, economic, technological and social aspects. [5] In addition to research, the transition to a circular economy also requires a process involving society as a whole. Active dialogue in all areas of society plays a decisive role in promoting understanding and acceptance of the circular economy. This includes intensive technical discussions between experts from business, science, politics, the media, environmental and consumer protection organisations as well as at national and local level. A collaborative, cross-value chain approach is therefore needed to achieve a circular economy.

Literature

[1] Bundesanstalt für Geowissenschaften und Rohstoffe (BGR), „Energierohstoffe 2009: Reserven, Ressourcen, Verfügbarkeit. Enthält Teil 1 bis 3. Stand: 10.11.2009,“ 2009. [Online]. Verfügbar unter:

https://www.bgr.bund.de/DE/Themen/Energie/Downloads/Energierohstoffe_2009_gesamt.pdf?__blob=publicationFile&v=2

[2] International Resource Panel, „Assessing global resource use: A systems approach to resource efficiency and pollution reduction: A Report of the International Resource Panel.,“ 2017. [Online]. Verfügbar unter: https://www.resourcepanel.org/reports/assessing-global-resource-use

[3] Circle Economy, „The circularity gap report 2023,“ 2023. [Online]. Verfügbar unter: https://assets-global.website-files.com/5e185aa4d27bcf348400ed82/63ecb3ad94e12d3e5599cf54_CGR%202023%20-%20Report.pdf

[4] Statista. „Weltbevölkerung 2023.“ Zugriff am: 18. Januar 2024. [Online.]

Verfügbar: https://de.statista.com/statistik/daten/studie/1716/umfrage/entwicklung-der-weltbevoelkerung/

[5] Bundesministerium für Bildung und Forschung (BMBF), „Ressourceneffiziente Kreislaufwirtschaft,“ 2018. [Online]. Verfügbar unter:

https://www.bmbf.de/SharedDocs/Publikationen/de/bmbf/7/31419_Ressourceneffiziente_Kreislaufwirtschaft.pdf?__blob=publicationFile&v=3

[6] A. Reichel, M. de Schoenmakere und J. Gillabel, „Circular economy in Europe: Developing the knowledge base (EEA report No. 2/2016).“ Luxembourg: Publications Office of the European Union, 2016.

[7] M. Schmelzer und A. Vetter, „Degrowth/Postwachstum zur Einführung,“ 3. Aufl. Hamburg: Junius, 2021.

[8] R. Steurer, „Die Wachstumskontroverse als Endlosschleife: Themen und Paradigmen im Rückblick,“ 2010. [Online].

Verfügbar unter: https://wachstumimwandel.at/wp-content/uploads/Steurer_2010_Wachstumskontroverse-als-Endlosschleife_WipolitBlaetter.pdf

[9] D. H. Meadows, D. L. Meadows, J. Randers und W. W. Behrens, „The Limits to Growth. A report for the Club of Rome‘s project on the predicament of mankind.,“ 1972. [Online]. Verfügbar unter: https://collections.dartmouth.edu/content/deliver/inline/meadows/pdf/meadows_ltg-001.pdf

[10] Die Bundesregierung, „Deutsche Nachhaltigkeitsstrategie Weiterentwicklung 2021,“ 2021. [Online].

Verfügbar unter: https://www.bundesregierung.de/resource/blob/998194/1875176/3d3b15cd92d0261e7a0bcdc8f43b7839/deutsche-nachhaltigkeitsstrategie-2021-langfassung-download-bpa-data.pdf

[11] C. Lindner, J. Schmitt und J. Hein, „Stoffstrombild Kunststoffe in Deutschland 2019,“ 7,9, 2020. [Online].

Verfügbar unter: https://www.conversio-gmbh.com/res/News_Media/2020/Kurzfassung_Stoffstrombild_2019.pdf

[12] B. Wohner, E. Pauer, V. Heinrich und M. Tacker, „Packaging-Related Food Losses and Waste: An Overview of Drivers and Issues“,

Sustainability, Jg. 11, Nr. 1, S. 264, 2019, doi: 10.3390/su11010264.

[13] Europäische Kommission, „Ein neuer Aktionsplan für die Kreislaufwirtschaft: Für ein saubereres und wettbewerbsfähigeres Europa,“ 2020. [Online]. Verfügbar unter: https://eur-lex.europa.eu/resource.html?uri=cellar:9903b325-6388-11ea-b735-01aa75ed71a1.0016.02/DOC_1&format=PDF

[14] J. Balwada, S. Samaiya und R. P. Mishra, „Packaging Plastic Waste Management for a Circular Economy and Identifying a better Waste Collection System using Analytical Hierarchy Process (AHP),“ Procedia CIRP, Jg. 98, S. 270–275, 2021, doi: 10.1016/j.procir.2021.01.102.

[15] Ellen MacArthur Foundation und McKinsey Center for Business and Environment, „Growth Within: a circular economy vision for a competitive Europe,“ 2015. [Online]. Verfügbar unter: https://emf.thirdlight.com/file/24/_A-BkCs_h7gRYB_Am9L_JfbYWF/Growth%20within%3A%20a%20circular%20economy%20vision%20for%20a%20competitive%20Europe.pdf

[16] R. Stark, G. Seliger und J. Bonvoisin, „Sustainable manufacturing: Challenges, solutions and implementation perspectives (Sustainable production, life cycle engineering and management).“ Cham: Springer Open, 2017. Zugriff am: 8. Januar 2024. [Online]. Verfügbar unter: https://library.oapen.org/bitstream/handle/20.500.12657/27791/1/1002214.pdf

[17] Europäische Kommission, „Der europäische Grüne Deal,“ 2019. Zugriff am: 4. August 2023. [Online].

Verfügbar unter: https://ec.europa.eu/commission/presscorner/detail/de/ip_19_6691

[18] European Commission, „Proposal for a regulation on packaging and packaging waste,“ PPWR, 2022. [Online].

Verfügbar unter: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52022PC0677

[19] C. Ingrao, M. Gigli und V. Siracusa, „An attributional Life Cycle Assessment application experience to highlight environmental hotspots in the production of foamy polylactic acid trays for fresh-food packaging usage,“ Journal of Cleaner Production, Jg. 150, S. 93–103, 2017, doi: 10.1016/j.jclepro.2017.03.007.

[20] E. Pauer, B. Wohner, V. Heinrich und M. Tacker, „Assessing the Environmental Sustainability of Food Packaging: An Extended Life Cycle Assessment including Packaging-Related Food Losses and Waste and Circularity Assessment,“ Sustainability, Jg. 11, Nr. 3, S. 925, 2019, doi: 10.3390/su11030925.

[21] L. M. Gruber, C. P. Brandstetter, U. Bos, J. P. Lindner und S. Albrecht, „LCA study of unconsumed food and the influence of consumer behavior,“ Int J Life Cycle Assess, Jg. 21, Nr. 5, S. 773–784, 2016, doi: 10.1007/s11367-015-0933-4.

[22] Ecoplus, BOKU, denkstatt und OFI, „Lebensmittel Verpackungen Nachhaltigkeit: Ein Leitfaden für Verpackungshersteller, Lebensmittelverarbeiter, Handel, Politik & NGOs,“ 2020. [Online]. Verfügbar unter: https://boku.ac.at/fileadmin/data/H03000/H81000/H81300/upload-files/Forschung/Lebensmittel/Leitfaden_StopWaste_A4_final_web.pdf

[23] G. Sposny, „Entwicklung und technische Umsetzung nachhaltiger thermoformbarer Verpackungen,“ in: Nachhaltiger Konsum, W. Wellbrock und

D. Ludin, Hg., Wiesbaden: Springer Fachmedien Wiesbaden, 2021, S. 521–535.

[24] S. Schmidt und W. Wellbrock, „Alltäglicher nachhaltiger Konsum – Bewusster Umgang mit Lebensmitteln vs. skandalträchtige Verschwendung,“

in: Nachhaltiger Konsum, W. Wellbrock und D. Ludin, Hg., Wiesbaden: Springer Fachmedien Wiesbaden, 2021, S. 719–741.

[25] T. Decker et al., „Plastikverpackungen in der Lebensmittelindustrie: Eine Analyse aus Sicht von VerbraucherInnen, Industrie und Handel,“ 2019. [Online]. Verfügbar unter: https://bmbf-plastik.de/sites/default/files/2019-11/Plastikverpackungen_in_der_Lebensmittelindustrie_Diskussionspapier_VerPlaPoS_2019-1.pdf

[26] Market Data Forecast, EUROPE FOOD PACKAGING MARKET: Segmented by Material, Product, Application and Country – Industry Analysis, Market Size, Growth Trends and Y-o-Y Forecasts 2021-2026, 2021. Zugriff am: 15. Dezember 2022.

[27] E. van den Beuken et al., „White paper | From #plasticfree to future-proof plastics,“ 2023. [Online]. Verfügbar unter:

[28] Z. Boz, V. Korhonen und C. Koelsch Sand, „Consumer Considerations for the Implementation of Sustainable Packaging: A Review,“ Sustainability, Jg. 12, Nr. 6, S. 2192, 2020, doi: 10.3390/su12062192.

[29] RECOUP, „Recyclability by Design 2022 with BPF - RECOUP.“ Zugriff am: 11. Januar 2024. [Online.]

Verfügbar: https://www.recoup.org/research-and-reports/recyclability-by-design-2022-with-bpf/

[30] K. Schüler, GVM Gesellschaft für Verpackungsmarktforschung mbH und Umweltbundesamt (UBA), „Aufkommen und Verwertung von Verpackungsabfällen in Deutschland im Jahr 2018: Abschlussbericht. Projektnummer 105802.,“ 2020. [Online]. Verfügbar unter:

https://www.umweltbundesamt.de/sites/default/files/medien/479/publikationen/texte_166-2020_aufkommen_und_verwertung_von_verpackungsabfaellen_in_deutschland_im_jahr_2018.pdf

[31] Y. Chae und Y.-J. An, „Current research trends on plastic pollution and ecological impacts on the soil ecosystem: A review,“ Environmental pollution (Barking, Essex : 1987), Early Access. doi: 10.1016/j.envpol.2018.05.008.

[32] L. Henderson und C. Green, „Making sense of microplastics? Public understandings of plastic pollution,“ Marine pollution bulletin,

Early Access. doi: 10.1016/j.marpolbul.2020.110908.

[33] L. S. Dilkes-Hoffman, J. L. Lane, T. Grant, S. Pratt, P. A. Lant und B. Laycock, „Environmental impact of biodegradable food packaging when considering food waste,“ Journal of Cleaner Production, Jg. 180, S. 325–334, 2018, doi: 10.1016/j.jclepro.2018.01.169.

[34] Umweltbundesamt, „PFAS sollen EU-weit beschränkt werden.“ Zugriff am: 15. Januar 2024. [Online.]

Verfügbar: https://www.umweltbundesamt.de/themen/pfas-sollen-eu-weit-beschraenkt-werden

[35] W. Leal Filho et al., „An overview of the problems posed by plastic products and the role of extended producer responsibility in Europe,“

Journal of Cleaner Production, Jg. 214, S. 550–558, 2019, doi: 10.1016/j.jclepro.2018.12.256.

[36] M. Shen et al., „Are biodegradable plastics a promising solution to solve the global plastic pollution?,“ Environmental pollution

(Barking, Essex: 1987), Early Access. doi: 10.1016/j.envpol.2020.114469.

[37] M. Liebig-Gonglach und H. Bednarz, „Mikro- und Nanoplastik im Trinkwasser: ein Gesundheitsrisiko?,“ Public Health Forum, Jg. 30, Nr. 4,

S. 247–251, 2022. doi: 10.1515/pubhef-2022-0082. [Online].

Verfügbar unter: https://www.degruyter.com/document/doi/10.1515/pubhef-2022-0082/html

[38] Europäische Union, RICHTLINIE (EU) 2019/904 DES EUROPÄISCHEN PARLAMENTS UND DES RATES über die Verringerung der Auswirkungen bestimmter Kunststoffprodukte auf die Umwelt: EU 2019/904, 2019.

[39] K. Istel, „Lebensmittelverpackungen im Vergleich,“ 2021. [Online]. Verfügbar unter: https://www.nabu.de/imperia/md/content/nabude/konsumressourcenmuell/211025-nabu-factsheet_verpackungsvergleiche.pdf

[40] A. Bardow et al., „KreislaufwirtschaftPLUS: Handlungsempfehlungen für eine Nationale Kreislaufwirtschaftsstrategie,“ 2022. [Online]. Verfügbar unter: https://plasticseurope.org/de/wp-content/uploads/sites/3/2022/11/2022-10-13-Handlungsempfehlungen-Nationale-Kreislaufwirtschaftsstrategie.pdf

[41] F. Müller et al., „Leitsätze einer Kreislaufwirtschaft,“ 2020. [Online]. Verfügbar unter: https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/2020_04_27_leitlinie_kreislaufwirtschaft_bf.pdf

[42] Gesetz zur Förderung der Kreislaufwirtschaft und Sicherung der umweltverträglichen Bewirtschaftung von Abfällen (Kreislaufwirtschaftsgesetz - KrWG): KrWG. Zugriff am: 8. Januar 2024. [Online]. Verfügbar unter: https://www.gesetze-im-internet.de/krwg/KrWG.pdf

[43] H. Wilts, „Deutschland auf dem Weg in die Kreislaufwirtschaft?,“ Jun. 2016. [Online]. Verfügbar unter: library.fes.de/pdf-files/wiso/12576.pdf

[44] P. Connett,„The Zero Waste Solution: Untrashing the Planet One Community at a Time.“ White River Junction, Vermont: Chelsea Green Publishing, 2013. [Online]. Verfügbar unter: https://ebookcentral.proquest.com/lib/kxp/detail.action?docID=5149131

[45] Ellen MacArthur Foundation, „Circular economy introduction: What is a circular economy?“ Zugriff am: 9. Januar 2024. [Online.]

Verfügbar: https://www.ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview

[46] Ellen MacArthur Foundation, „Towards the circular economy Vol. 1: an economic and business rationale for an accelerated transition,“ 2013. [Online]. Verfügbar unter: https://emf.thirdlight.com/file/24/xTyQj3oxiYNMO1xTFs9xT5LF3C/Towards%20the%20circular%20economy%20Vol%201%3A%20an%20economic%20and%20business%20rationale%20for%20an%20accelerated%20transition.pdf

[47] M. Braungart, W. McDonough und A. Bollinger, „Cradle-to-cradle design: creating healthy emissions – a strategy for eco-effective product and system design,“ Journal of Cleaner Production, Jg. 15, 13-14, S. 1337–1348, 2007, doi: 10.1016/j.jclepro.2006.08.003.

[48] C. Wiese, N. Krebs und K. Ketelhake. „Your Goal –Your Action: Input - Die Konsistenzstrategie/ auch Ökoeffektivität genannt,“

Zugriff am: 4. Februar 2023. [Online.]

Verfügbar: https://www.uni-hildesheim.de/deinprojekt/topic/input-die-konsistenzstrategie-auch-o%CC%88koeffektivita%CC%88t-genannt/

[49] T. T. Tambovceva, L. H. Melnyk, I. B. Dehtyarova und S. O. Nikolaev, „Circular Economy: Tendencies and Development Perspectives,“

Meh. regul. ekon., Jg. 2021, Nr. 2, S. 33–42, 2021, doi: 10.21272/mer.2021.92.04.

[50] P. Ghisellini, C. Cialani und S. Ulgiati, „A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems,“ Journal of Cleaner Production, Jg. 114, S. 11–32, 2016. doi: 10.1016/j.jclepro.2015.09.007. [Online].

Verfügbar unter: https://www.sciencedirect.com/science/article/pii/s0959652615012287

[51] Europäische Kommission, RICHTLINIE 2008/98/EG DES EUROPÄISCHEN PARLAMENTS UND DES RATES vom 19. November 2008 über Abfälle: zuletzt geändert am 14.06.2018, 2008. Zugriff am: 4. August 2023. [Online].

Verfügbar unter: https://eur-lex.europa.eu/legal-content/DE/TXT/PDF/?uri=CELEX:02008L0098-20180705

[52] U. Lange und K. Surdyk, „Ressourceneffizienz in der Wertschöpfungskette (Nr. 23).“ VDI Zentrum Ressourceneffizienz, 2018. [Online].

Verfügbar unter: https://digital.zlb.de/viewer/metadata/34163937/1/

[53] Bundesministerium für Umwelt, Naturschutz und nukleare Sicherheit und Verbraucherschutz (BMUV). „Ökologische Produktgestaltung (Ökodesign).“ Zugriff am: 28. Juli 2023. [Online.]

Verfügbar: https://www.bmuv.de/themen/nachhaltigkeit-digitalisierung/konsum-und-produkte/oekologische-produktgestaltung-oekodesign

[54] Europäisches Parlament, „Kreislaufwirtschaft: Definition und Vorteile,“ Aktuelles | Europäisches Parlament, 2023. Zugriff am: 11. Januar 2024. [Online].

Verfügbar unter: https://www.europarl.europa.eu/news/de/headlines/economy/20151201STO05603/kreislaufwirtschaft-definition-und-vorteile

[55] Europäische Kommission, „Vorschlag für eine VERORDNUNG DES EUROPÄISCHEN PARLAMENTS UND DES RATES zur Schaffung eines Rahmens für die Festlegung von Ökodesign-Anforderungen für nachhaltige Produkte und zur Aufhebung der Richtlinie 2009/125/EG, 2022.“

Zugriff am: 11. September 2023. [Online].

Verfügbar unter: https://eur-lex.europa.eu/resource.html?uri=cellar:bb8539b7-b1b5-11ec-9d96-01aa75ed71a1.0003.02/DOC_1&format=PDF

[56] T. C. McAloone und N. Bey, „Environmental improvement through product development A guide,“ 2009. [Online].

Verfügbar unter: https://backend.orbit.dtu.dk/ws/portalfiles/portal/3996106/mpu-elektronisk-uk.pdf

[57] T. C. McAloone und D. C. A. Pigosso, „Ökodesign,“ in Pahl/Beitz Konstruktionslehre, B. Bender und K. Gericke, Hg., Berlin, Heidelberg:

Springer Berlin Heidelberg, 2021, S. 975–1021.

[58] M. Möller, „Methoden und Hilfsmittel des Ecodesigns von Kunststoffverpackungen - Technische Dokumentation,“ 2016. [Online].

Verfügbar unter: https://www.bkv-gmbh.de/files/bkv-neu/studien/Studie_zum_Eco_Design_von_Kunststoffverpackungen.pdf

[59] D. Jepsen, T. Zimmermann und L. Rödig. „Kernleitfaden Ökodesign von Kunststoffverpackungen.“ Zugriff am: 11. Januar 2024. [Online.]

Verfügbar: https://ecodesign-packaging.org/en/guidelines/overview/

[60] T. Pitschke, S. Kreibe, M. Schlummer und B. Hanschmann, „Recyclingfähigkeit von Verpackungen: Bewertungskatalog,“ 2021. [Online].

Verfügbar unter: https://www.interzero.de/fileadmin/Verpackungsoptimierung/Bewertungskatalog_Recyclingfaehigkeit_Interseroh.pdf

[61] Zentrale Stelle Verpackungsregister (ZSVR), „Mindeststandard für die Bemessung der Recyclingfähigkeit von systembeteiligungspflichtigen Verpackungen gemäß § 21 Abs. 3 VerpackG: im Einvernehmen mit dem Umweltbundesamt,“ 2022. [Online].

Verfügbar unter: https://www.verpackungsregister.org/fileadmin/files/Mindeststandard/Mindeststandard_VerpackG_Ausgabe_2022.pdf

[62] RECOUP, „Recyclability by Design 2023 - RECOUP.“ Zugriff am: 11. Januar 2024. [Online.]

Verfügbar: https://www.recoup.org/research-and-reports/recoup-recyclability-by-design-2023/

[63] RecyClass, „Design for Recycling Guidelines - RecyClass.“ Zugriff am: 10. Januar 2023. [Online.]

Verfügbar: https://recyclass.eu/recyclability/design-for-recycling-guidelines/

[64] Initiative Frosch, „Design for Recycling: Die Grundlage der Kreislaufwirtschaft | Initiative Frosch.“ Zugriff am: 9. Januar 2024. [Online.]

Verfügbar: https://initiative-frosch.de/design-for-recycling-die-grundlage-der-kreislaufwirtschaft/

[65] United Nations, „Sustainable Development Goals - SDG 12 Sustainable consumption and production.“ Zugriff am: 11. Januar 2024. [Online.] Verfügbar: https://www.un.org/sustainabledevelopment/sustainable-consumption-production/

[66] F. Wikström, H. Williams, J. Trischler und Z. Rowe, „The Importance of Packaging Functions for Food Waste of Different Products in Households,“ Sustainability, Jg. Jg. 11,, Nr. 9, S. 2641, 2019, doi: 10.3390/su11092641.

[67] United Nations. „Goal 2: Zero Hunger - United Nations Sustainable Development.“ Zugriff am: 11. Januar 2024. [Online.]

Verfügbar: https://www.un.org/sustainabledevelopment/hunger/

[68] J. Martens und W. Obenland, „Die Agenda 2030: Globale Zukunftsziele für nachhaltige Entwicklung,“ 30. Aufl. Bonn, Osnabrück:

Global Policy Forum; terre des hommes, 2017. Zugriff am: 8. Januar 2024. [Online].

Verfügbar unter: https://www.2030agenda.de/sites/default/files/Agenda_2030_online.pdf

[69] KUNSTSTOFF.swiss, „Kunststoffe für eine nachhaltige Zukunft.“ Zugriff am: 8. Januar 2024. [Online.]Verfügbar: https://kunststoff.swiss/Nachhaltigkeit/Kunststoffe-f%C3%BCr-eine-nachhaltige-Zukunft

[70] Gesellschaft für Verpackungsmarktforschung, denkstatt GmbH, „Nutzen von Verpackungen: „Verpackungen nutzen - auch in ökologischer Hinsicht“,“ Mainz, Apr. 2018. [Online].

Verfügbar unter: https://www.agvu.de/wp-content/uploads/2018/09/Verpackungen-nutzen-auch-in-%C3%B6kologischer-Hinsicht.pdf

[71] Europäische Kommission, „MITTEILUNG DER KOMMISSION AN DAS EUROPÄISCHE PARLAMENT, DEN RAT, DEN EUROPÄISCHEN WIRTSCHAFTS- UND SOZIALAUSSCHUSS UND DEN AUSSCHUSS DER REGIONEN Eine europäische Strategie für Kunststoffe in der Kreislaufwirtschaft,“ 2018. [Online].

Verfügbar unter: https://eur-lex.europa.eu/resource.html?uri=cellar:2df5d1d2-fac7-11e7-b8f5-01aa75ed71a1.0002.02/DOC_3&format=PDF

[72] Europäische Union, RICHTLINIE (EU) 2019/904 DES EUROPÄISCHEN PARLAMENTS UND DES RATES über die Verringerung der Auswirkungen bestimmter Kunststoffprodukte auf die Umwelt: EU 2019/904, 2019. [Online].

Verfügbar unter: eur-lex.europa.eu/legal-content/DE/TXT/PDF/

[73] L. Copello, T. Mörsen, D. Napierska, J. Vahk und L. Veillard, „Feedback on the EU Packaging Regulation revision: Recommendations for an ambitious revision of the Packaging and Packaging Waste Regulation (PPWR),“ (Position Paper PPWR zerowasteeurope.eu), 2023. [Online]. Verfügbar unter: https://zerowasteeurope.eu/wp-content/uploads/2023/04/Position-Paper-PPWR-2.pdf

[74] F. Schoettker. „EU-Verpackungsordnung Ante Portas! - Statement der IK.“ Zugriff am: 13. November 2023. [Online.]

Verfügbar: https://newsroom.kunststoffverpackungen.de/2023/11/07/ik-jahresbericht-eu-verpackungsordnung-ante-portas/?utm_campaign=newsletter&utm_medium=email&utm_source=es

[75] G. K. Deshwal, N. R. Panjagari und T. Alam, „An overview of paper and paper based food packaging materials: health safety and environmental concerns,“ J. Food. Sci. Technol. (New Delhi, India), Early Access. doi: 10.1007/s13197-019-03950-z.

[76] K. Molina-Besch, F. Wikström und H. Williams, „The environmental impact of packaging in food supply chains—does life cycle assessment of food provide the full picture?,“ Int. J. Life Cycle Assess., Jg. 24, Nr. 1, S. 37–50, 2019, doi: 10.1007/s11367-018-1500-6.

[77] Europäischen Union, Verordnung (EU) 2022/1616 über Materialien und Gegenstände aus recyceltem Kunststoff, die dazu bestimmt sind, mit Lebensmitteln in Berührung zu kommen, und zur Aufhebung der Verordnung (EG) Nr. 282/2008: Verordnung (EU) 2022/1616, 2022. [Online]. Verfügbar unter: https://eur-lex.europa.eu/legal-content/DE/TXT/PDF/?uri=CELEX:32022R1616

[78] Gesetz über das Inverkehrbringen, die Rücknahme und die hochwertige Verwertung von Verpackungen (Verpackungsgesetz – VerpackG): VerpackG. Zugriff am: 8. Januar 2024. [Online]. Verfügbar unter: https://www.gesetze-im-internet.de/verpackg/VerpackG.pdf

[79] Lizenzero, „Nachhaltige Verpackungsgestaltung: Was bedeutet recyclingfähig?“ Zugriff am: 23. Januar 2024. [Online.]

Verfügbar: https://www.lizenzero.de/blog/nachhaltige-verpackungsgestaltung-was-bedeutet-recyclingfaehig/

[80] R. Pomberger, „Über theoretische und reale Recyclingfähigkeit,“ Österr Wasser- und Abfallw, Jg. 73, 1-2, S. 24–35, 2021, doi: 10.1007/s00506-020-00721-5.

[81] D. Bechlarz, „Was ermöglicht Carbon Capture and Utilisation?,“ PLASTVERARBEITER, 18. Juli 2023. Zugriff am: 23. Januar 2024. [Online.] Verfügbar: https://www.plastverarbeiter.de/roh-und-zusatzstoffe/was-ermoeglicht-carbon-capture-and-utilisation-839.html

[82] Europäisches Parlament, RICHTLINIE 94/62/EG DES EUROPÄISCHEN PARLAMENTS UND DES RATES vom 20. Dezember 1994 über Verpackungen und Verpackungsabfälle, 2018. [Online]. Verfügbar unter: https://eur-lex.europa.eu/legal-content/DE/TXT/PDF/?uri=CELEX:01994L0062-20180704

[83] eurostat, „Recycling von Verpackungsabfällen nach Art der Verpackung.“ Zugriff am: 15. Januar 2024. [Online.]

Verfügbar: https://ec.europa.eu/eurostat/databrowser/view/cei_wm020/default/table?lang=de

[84] Zentrale Stelle Verpackungsregister (ZSVR), „Recyclingquoten 2021,“ 2022. [Online].

Verfügbar unter: https://www.verpackungsregister.org/fileadmin/Auswertungen/ZSVR_Auswertung_Recyclingquoten_2018-2021.pdf

[85] European Parliament, „P9_TA(2023)0425 Packaging and packaging waste Amendments* adopted by the European Parliament on 22 November 2023 on the proposal for a regulation of the European Parliament and of the Council on packaging and packaging waste, amending Regulation (EU) 2019/1020 and Directive (EU) 2019/904, and repealing Directive 94/62/EC (COM(2022)0677 – C9-0400/2022 – 2022/0396(COD)),“ 2023. [Online]. Verfügbar unter: https://www.europarl.europa.eu/doceo/document/TA-9-2023-0425_EN.pdf

[86] Bundesministerium für Umwelt, Naturschutz, nukleare Sicherheit und Verbraucherschutz (BMUV) und www.bmuv.de, „Weniger Verpackungsmüll – mehr Wahlfreiheit – Schluss mit Mogelpackungen | ECKPUNKTE zum Gesetz für weniger Verpackungsmüll,“ 2023. [Online].

Verfügbar unter: https://www.bmuv.de/fileadmin/Daten_BMU/Download_PDF/Abfallwirtschaft/weniger_verpackungsmuell_eckpunkte_bf.pdf

[87] eurostat. „Material flow accounts statistics - material footprints.“ Zugriff am: 19. Januar 2024. [Online.]

Verfügbar: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Material_flow_accounts_statistics_-_material_footprints#EU.27s_material_footprint_by_material_category_over_time

[88] Dr. Martin R. Stuchtey, „Circular Economy: Werte schöpfen, Kreisläufe schließen,“ Jan. 2016. [Online].

Verfügbar unter: https://320grad.de/wp-content/uploads/2016/01/Studie1.pdf

[89] Ministerium für Landwirtschaft, Umwelt und Klimaschutz des Landes Brandenburg, „Rezyklateinsatz stärken (RESAG): Bericht an die Umweltministerkonferenz (UMK),“ Jan. 2022. [Online].

Verfügbar unter: https://mluk.brandenburg.de/sixcms/media.php/9/RESAG-Bericht%202022-01-28.pdf

[90] Sachverständigenrat für Umweltfragen (SRU), „Kreislaufwirtschaft: Von der Rhetorik zur Praxis,“ [Online].

Verfügbar unter: https://www.umweltrat.de/SharedDocs/Downloads/DE/01_Umweltgutachten/2016_2020/2020_Umweltgutachten_Kap_03_Kreislaufwirtschaft.pdf?__blob=publicationFile&v=2

[91] Ministerium für Landwirtschaft, Umwelt und Klimaschutz des Landes Brandenburg, „Rezyklateinsatz stärken (RESAG): Bericht an die Umweltministerkonferenz (UMK),“ 2022. [Online].

Verfügbar unter: https://mluk.brandenburg.de/sixcms/media.php/9/RESAG-Bericht%202022-01-28.pdf

[92] V. Giordano und Andre de Fontaine, „Die Vorteile der Kreislaufwirtschaft,“ springerprofessional.de, 11. Mai 2021. Zugriff am: 11. Januar 2024. [Online.] Verfügbar: https://www.springerprofessional.de/energie---nachhaltigkeit/entsorgung/die-vorteile-der-kreislaufwirtschaft/19138588

[93] Arbeitsgemeinschaft Verpackung und Umwelt (AGVU), „Aktuelles zu Verpackung und Nachhaltigkeit: Materialfraktion Glas.“

Zugriff am: 15. Dezember 2023. [Online.] Verfügbar: https://www.agvu.de/de/125-125/

[94] Arbeitsgemeinschaft Verpackung und Umwelt (AGVU), „Aktuelles zu Verpackungen und Nachhaltigkeit: Materialfraktion Weißblech.“

Zugriff am: 15. Dezember 2023. [Online.] Verfügbar: https://www.agvu.de/de/weissblech-153/

[95] Umweltbundesamt, „Recyclingpapier ist gut für die Umwelt.“ Zugriff am: 19. Januar 2024. [Online.]

Verfügbar: https://www.umweltbundesamt.de/umwelttipps-fuer-den-alltag/haushalt-wohnen/papier-recyclingpapier#hintergrund

[96] G. Bovensiepen, H. Fink, P. Schnück, S. Rumpff und S. Raimund, „Verpackungen im Fokus: Die Rolle von Circular Economy auf dem Weg zu mehr Nachhaltigkeit,“ 2018. [Online].

Verfügbar unter: https://www.pwc.de/de/handel-und-konsumguter/pwc-studie-verpackungen-im-fokus-februar-2018-final.pdf

[97] T. Decker et al., „Verbraucherreaktionen bei Plastik und dessen Vermeidungsmöglichkeiten am Point of Sale (VerPlaPoS). Abschlussbericht,“ 2021. [Online]. Verfügbar unter: https://www.researchgate.net/profile/Sven-Saengerlaub/publication/352440875_Verbraucherreaktionen_bei_Plastik_und_dessen_Vermeidungsmoglichkeiten_am_Point_of_Sale_VerPlaPoS_Abschlussbericht/links/60c9d7f9458515dcee9377ac/Verbraucherreaktionen-bei-Plastik-und-dessen-Vermeidungsmoeglichkeiten-am-Point-of-Sale-VerPlaPoS-Abschlussbericht.pdf#page=132

[98] Statista, „Österreich - Kaufentscheidungskriterien bei Produkten des täglichen Bedarfs 2018 | Statista.“ Zugriff am: 19. Januar 2024. [Online.] Verfügbar: https://de.statista.com/statistik/daten/studie/829315/umfrage/umfrage-zu-kaufentscheidungskriterien-bei-produkten-des-taeglichen-bedarfs-in-oesterreich/